English

+86-21-57450120

+86-18221926197

+86-18221926197

No.1418 Zhuangliang Road, Zhuanghang Town, Fengxian District, Shanghai 201415, P.R. China

Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

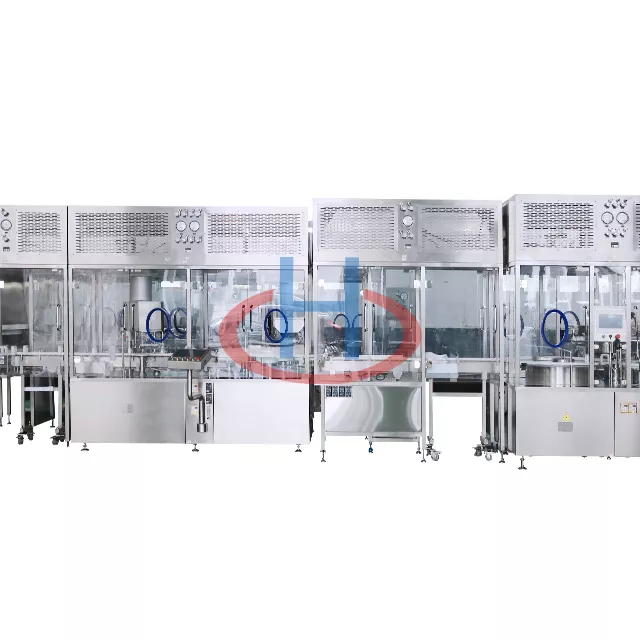

The evolution of industrial automation has significantly transformed the manufacturing landscape, with the filling machine playing a pivotal role in the packaging industry. These machines are indispensable in various sectors, including food and beverage, pharmaceuticals, and cosmetics, where they enhance efficiency, precision, and productivity. This article delves into the intricate workings of filling machines, exploring their types, operational principles, and the technological advancements that have made them essential in modern manufacturing processes.

Filling machines are categorized based on the type of product they handle and the method of operation. The primary types include liquid filling machines, powder filling machines, paste filling machines, and granular filling machines. Each type is designed to accommodate the specific characteristics of the product being filled, such as viscosity, particle size, and flowability.

Liquid filling machines are widely used in industries that require the packaging of liquid products, such as beverages, oils, and chemicals. These machines are designed to handle liquids of varying viscosities, from water-like fluids to thicker substances like syrups and shampoos. The operational principle typically involves the use of pumps, such as gear pumps or piston pumps, to transfer the liquid from a storage tank to the container. The precision of these machines ensures that each container is filled to the exact required volume, minimizing waste and ensuring consistency.

Powder filling machines are essential in industries dealing with powdered products, such as pharmaceuticals, food additives, and chemicals. These machines utilize various mechanisms, including auger fillers and vibratory fillers, to accurately dispense powders into containers. The challenge with powder filling lies in ensuring that the powder flows smoothly without clogging, which is addressed through the use of specialized feeding systems and sensors.

Paste filling machines are designed for products with high viscosity, such as creams, gels, and pastes. These machines often incorporate piston fillers that use a piston to draw the paste from a hopper and dispense it into containers. The design of paste filling machines ensures that they can handle thick substances without air entrapment, which is crucial for maintaining product quality and shelf life.

The operational principles of filling machines vary depending on the type of machine and the product being filled. However, the core components and processes remain consistent across different machines. Key components include the product storage tank, filling nozzles, pumps, and control systems.

The filling process typically begins with the product being stored in a tank. From there, it is transferred to the filling nozzles through a pump system. The nozzles are designed to ensure precise dispensing of the product into containers, which are transported via a conveyor system. Sensors and control systems are employed to monitor the filling process, ensuring accuracy and preventing spillage or overfilling.

Modern filling machines are equipped with advanced control systems that enhance their efficiency and flexibility. These systems allow operators to adjust filling parameters, such as volume and speed, to accommodate different product types and container sizes. Additionally, control systems facilitate the integration of filling machines into automated production lines, enabling seamless operation and real-time monitoring.

The filling machine industry has witnessed significant technological advancements, driven by the need for greater efficiency, precision, and versatility. Innovations such as servo-driven systems, electronic control interfaces, and automated cleaning systems have transformed filling machines into sophisticated pieces of equipment capable of handling a wide range of products and production demands.

Servo-driven systems have revolutionized the filling machine industry by providing precise control over the filling process. These systems use servo motors to control the movement of filling nozzles and pumps, allowing for accurate and repeatable filling operations. The use of servo-driven systems also enhances the flexibility of filling machines, enabling them to handle different product viscosities and container sizes with ease.

Electronic control interfaces have become a standard feature in modern filling machines, providing operators with an intuitive platform to manage the filling process. These interfaces allow for easy adjustment of filling parameters, real-time monitoring of machine performance, and integration with other production line equipment. The ability to store and recall filling recipes further enhances the efficiency of production operations.

Automated cleaning systems have been developed to address the challenges of maintaining hygiene and preventing cross-contamination in filling operations. These systems automate the cleaning of filling nozzles, pumps, and product pathways, reducing downtime and ensuring compliance with stringent hygiene standards. The implementation of automated cleaning systems is particularly beneficial in industries such as food and pharmaceuticals, where product safety is paramount.

Filling machines are integral to the efficiency and success of modern manufacturing processes. Their ability to handle a diverse range of products with precision and speed makes them invaluable in various industries. As technology continues to advance, filling machines will undoubtedly become even more sophisticated, offering enhanced capabilities and further streamlining production operations. For businesses looking to optimize their packaging processes, investing in a filling machine is a strategic decision that promises significant returns in terms of productivity and product quality.