English

+86-21-57450120

+86-18221926197

+86-18221926197

No.1418 Zhuangliang Road, Zhuanghang Town, Fengxian District, Shanghai 201415, P.R. China

Views: 0 Author: Site Editor Publish Time: 2026-01-16 Origin: Site

Selecting the right equipment for a production line is often a high-stakes decision where visual similarities can be deceiving. While a liquid filler and a paste filler may look nearly identical on the shop floor, the engineering principles governing them differ radically. A machine designed to flow water by gravity will fail catastrophically if tasked with moving cold peanut butter, just as a high-force piston filler may turn a foamy chemical cleaner into a splashing mess.

The leading cause of production bottlenecks in packaging facilities is the "Viscosity Trap." This occurs when decision-makers select equipment based solely on a product’s current viscosity, ignoring critical variables like temperature shifts, particulate content, or future product line expansions. A misjudgment here results in frequent downtime, inconsistent fill volumes, and excessive waste. This article moves beyond basic definitions to provide a technical comparison of liquid filling machines and paste filling machines, focusing on ROI, maintenance realities, and mechanism suitability.

Mechanism Divergence: Liquid fillers typically rely on gravity, overflow, or flow meters, whereas paste fillers require force-driven systems like pistons or rotary pumps to move viscous material.

Hygiene & Maintenance: Paste fillers generally require higher "strip-down" maintenance time compared to the CIP (Clean-In-Place) capabilities common in liquid systems.

Accuracy vs. Aesthetics: Liquid machines (specifically overflow) prioritize visual fill levels; paste machines prioritize volumetric precision to prevent costly product giveaway.

The Flexibility Factor: "Hybrid" machines exist but often compromise on speed; dedicated equipment is usually required for high-throughput lines handling distinct viscosities.

To understand why specific machinery is required, we must first look at the physics of the product itself. The defining characteristic separating liquid applications from paste applications is not just thickness; it is how the material responds to force and gravity.

Manufacturers categorize fluids based on centipoise (cP), a dynamic viscosity measurement. Free-flowing liquids generally possess low cP values, similar to water, spirits, or thin vegetable oils. These fluids conform instantly to the shape of their container. They require minimal force to move; gravity alone is often sufficient to induce flow through a nozzle.

In contrast, viscous pastes and semi-solids exhibit high resistance to flow. Products like peanut butter, heavy cosmetic creams, and mascara do not flow freely. They require positive displacement—mechanical force—to shear the product and push it through the system. Paste filling machines are engineered to generate this specific type of force without degrading the product's texture.

Viscosity is rarely static. A product can transition from a "paste" to a "liquid" state simply by applying heat. Waxes, heavy honeys, and certain petroleum jellies may behave like solids at room temperature but flow like water when heated to 80°C.

This creates a critical decision factor for buyers. If a facility lacks strict temperature control, or if the product cools rapidly during the transfer from tank to bottle, a simple gravity filler will clog. In these scenarios, a paste filler equipped with a heated hopper and jacketed fluid path becomes a necessity, even if the product flows freely when hot. The equipment must be rated for the product's "worst-case" viscosity, not its ideal state.

The internal composition of the fluid also dictates machine selection. Liquids are generally homogeneous. Pastes, however, frequently contain suspended solids. Consider strawberry yogurt with fruit chunks or facial scrubs with exfoliant beads.

Standard liquid fillers use small valves and screens that will instantly block or crush these particulates. Paste filling equipment utilizes large rotary valves with wide clearances designed specifically to pass solids without damage. Attempting to run a particulate-heavy sauce through a standard liquid valve is a recipe for immediate blockage and equipment failure.

The core divergence between these machine types lies in how they measure and move the product. Liquid systems often prioritize speed and level, while paste systems prioritize force and volume.

Gravity Fillers operate on a simple principle: time-based valve opening. A supply tank sits above the nozzles, and gravity pulls the fluid down. The machine opens the valve for a set duration (e.g., 2.5 seconds) to deliver a specific volume. These systems offer a low Total Cost of Ownership (TCO) and are best suited for thin, non-foaming liquids where high precision is not critical.

Overflow Fillers (Fill-to-Level) are unique to the liquid category. They utilize a dual-nozzle system that forces fluid into the bottle while simultaneously sucking excess fluid back into the reservoir. The primary goal is cosmetic. It ensures every bottle on a retail shelf appears filled to the exact same height, regardless of minor irregularities in the glass or plastic. This visual consistency is critical for retail cosmetics, beverages, and household cleaners sold in clear containers.

Gravity cannot move paste. Therefore, paste filling machines rely on positive displacement.

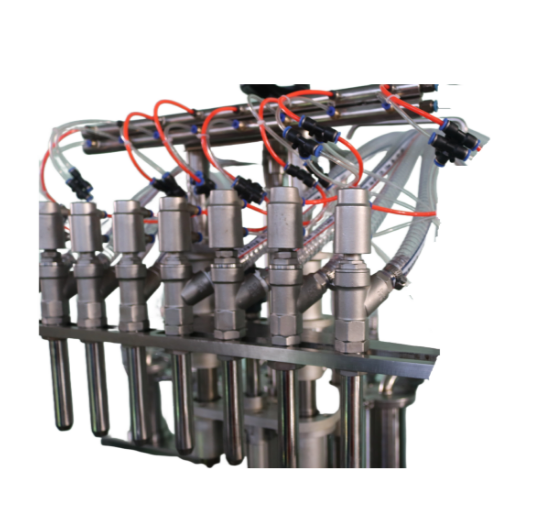

Piston Fillers are the industry standard for high-viscosity products. A cylinder draws the product in on the backstroke and forces it out on the forward stroke. The advantage here is the ability to handle heavy viscosity without cavitation. The mechanical action creates a powerful vacuum that pulls thick product into the chamber, ensuring a full fill every cycle.

Progressive Cavity and Rotary Pumps are used for continuous flow applications. These systems use a rotor and stator to move product through sealed cavities. They are excellent for shear-sensitive products but can be more expensive to maintain than simple piston systems.

| Feature | Liquid Filling Machine (Overflow/Gravity) | Paste Filling Machine (Piston) |

|---|---|---|

| Primary Force | Gravity or Low Pressure | Mechanical Force / Positive Displacement |

| Fill Principle | Fill-to-Level (Cosmetic) or Time-Based | Volumetric (Exact Quantity) |

| Viscosity Range | Water-thin to Light Oils | Thick Creams to Heavy Pastes |

| Particulates | Cannot handle solids | Handles suspended solids well |

Drip control is another area where engineering differs. Liquid fillers typically use simple mesh screens or positive shut-off nozzles to stop the flow. Because the fluid has low surface tension, it cuts off cleanly.

Pastes are sticky and prone to "stringing." If a nozzle simply closes, a long string of product (like honey or glue) may trail from the nozzle, coating the outside of the bottle or the conveyor belt. Paste fillers require specialized "blow-off" or "suck-back" nozzles. These mechanisms physically retract a small amount of product or use a burst of air to sever the string, ensuring a clean cut-off after every cycle.

Beyond the physics of filling, the operational realities of running these machines on a daily basis differ significantly. Managers must anticipate different labor requirements for cleaning and changeovers.

Hygiene protocols drive downtime. Liquid systems are often compatible with Clean-In-Place (CIP) systems. Operators can flush hot water and cleaning agents through the lines without dismantling the machine. This results in high uptime and minimal labor costs during product swaps.

Paste systems rarely offer true CIP capabilities for standard piston fillers. Thick products adhere stubbornly to cylinder walls, O-rings, and valves. These machines often require "Clean-Out-of-Place" (COP), necessitating manual disassembly. Operators must physically remove pistons, scrub seals, and inspect valves. Buyers must factor in 20–40% longer changeover times for paste lines when calculating Overall Equipment Effectiveness (OEE).

Physics dictates speed. Liquid filling machines generally achieve higher Bottles Per Minute (BPM) rates because the fluid creates less friction and can move through lines rapidly without degradation.

Pastes require slower fill speeds. Moving a viscous product too quickly can cause air entrapment, resulting in unsightly bubbles visible in glass jars. Furthermore, aggressive speeds can cause splashing or "tunnelling" within the hopper. Paste filling is a game of controlled force, which naturally limits top-end speed compared to water-thin applications.

The container itself acts as a constraint. Liquid fillers exert minimal pressure on the bottle, allowing them to fill flexible pouches and rigid glass equally well. Paste fillers, particularly piston types, generate significant injection pressure. If the container is a thin-walled plastic jar, this pressure can deform or crush the package. Additionally, thick pastes require bottom-up filling capabilities—where the nozzle dives to the bottom of the container and rises as it fills—to prevent large air pockets from forming at the base.

Attempting to force the wrong machine to handle a product is not just inefficient; it is often destructive. Here are the specific risks associated with mismatched equipment.

If you attempt to run a thick cream through a gravity or overflow filler, the result is pump starvation and cavitation. The gravity pressure is insufficient to push the mass through the nozzle, leading to inconsistent fill volumes—one bottle might be 50% full, the next 80%. Worse, the motor may burn out trying to drive a pump that cannot move the resistance.

The "stringing" issue also becomes unmanageable. Without the specialized shear nozzles of a paste filler, the product will coat the threads of the bottle. This leads to cap failure (caps won't seal properly on dirty threads) and labeling failure, as the sticky product transfers to the outside of the container.

Technically, a piston filler can move water. However, it is an inefficient and messy choice. The force generated by a piston is often too aggressive for thin liquids. As the product shoots into the bottle, it splashes violently, bouncing out of the neck and wasting material.

Leakage is another concern. The seals and O-rings in a paste filler are designed with clearances for thick products. Low-viscosity fluids (like alcohol or water) can sometimes leak past these heavy-duty seals, leading to dripping nozzles and a constantly wet production floor.

Choosing between these technologies requires a systematic approach. Decision-makers should follow a three-step audit to ensure the investment matches the application.

Do not guess viscosity. Terms like "thick" or "runny" are subjective. Send product samples to the machinery manufacturer for testing at the specific filling temperature. A product that is 5,000 cP at 20°C might be 500 cP at 40°C. Knowing the exact rheology ensures the pump and nozzle are sized correctly.

Analyze how the product is sold and marketed. If the product is expensive (e.g., CBD oil, essential oils, premium anti-aging creams) and sold by strict weight/volume regulatory requirements, a Piston or Volumetric Filler is the superior choice regardless of viscosity. It eliminates "giveaway" (overfilling). Conversely, if the product is a budget shampoo sold in a clear retail bottle where shelf appearance is paramount, an Overflow Liquid Filler is the correct strategic choice to ensure visual uniformity.

For facilities that pack a wide range of products—from toners to lotions—dedicated machines for each type may take up too much floor space. In this case, Servo-Driven Pump Fillers offer a middle ground. These machines use sophisticated programming to alter the pump's speed and dwell time.

A servo filler can simulate the slow, high-torque push needed for a paste, and then be reprogrammed to run a fast, low-torque cycle for a liquid. The trade-off is a higher initial capital expenditure (CapEx) compared to dedicated gravity or mechanical piston fillers, but the versatility provides a hedge against changing market trends.

The choice between liquid and paste filling machines is dictated by physics, economics, and aesthetics. Liquid fillers thrive on gravity and speed, prioritizing visual fill levels and ease of cleaning. Paste fillers rely on brute force and volumetric precision, handling complex textures and particulates at the cost of longer maintenance intervals.

For dedicated production lines running a single product type, specialized machines offer the best Total Cost of Ownership. However, for contract packagers (co-packers) handling high variety, servo-pump hybrids offer necessary flexibility. Before signing a purchase order, we strongly encourage readers to request a material testing consultation to validate their specific product against machine capabilities.

A: Yes, typically servo-driven pump fillers or certain piston fillers can handle both, but they are not "plug and play." Significant changeover times are required to swap nozzles, adjust pump speeds, and change seals. Gravity fillers absolutely cannot handle paste. For high-efficiency lines, dedicated machines are always preferred over "all-in-one" solutions.

A: Piston fillers (common for pastes) and flow-meter fillers (for liquids) offer the highest volumetric accuracy. They physically measure the product volume, often achieving accuracy within ±0.5%. Overflow fillers are less volumetrically accurate but provide 100% visual fill level accuracy.

A: Dripping usually indicates an issue with the nozzle cut-off mechanism. It implies the "suck-back" setting is too weak, the nozzle size is incorrect for the viscosity, or the product temperature is too high (lowering viscosity beyond the machine's setup). Worn O-rings in the shut-off valve are another common culprit.

A: Volumetric filling ensures a specific amount of product (e.g., exactly 500ml) enters the container, regardless of whether the bottle looks full. Liquid level (overflow) filling ensures the bottle looks full to a specific cosmetic line near the neck, even if the actual volume inside varies slightly due to inconsistencies in the glass thickness.