HaoChao: Your Premier Filling Machine Manufacturer

Welcome to HaoChao, a leading manufacturer of high-quality filling machines. Our commitment to innovation, precision, and customer satisfaction has made us a trusted partner for businesses worldwide. Discover how our advanced filling machines can streamline your production process and ensure top-quality output.

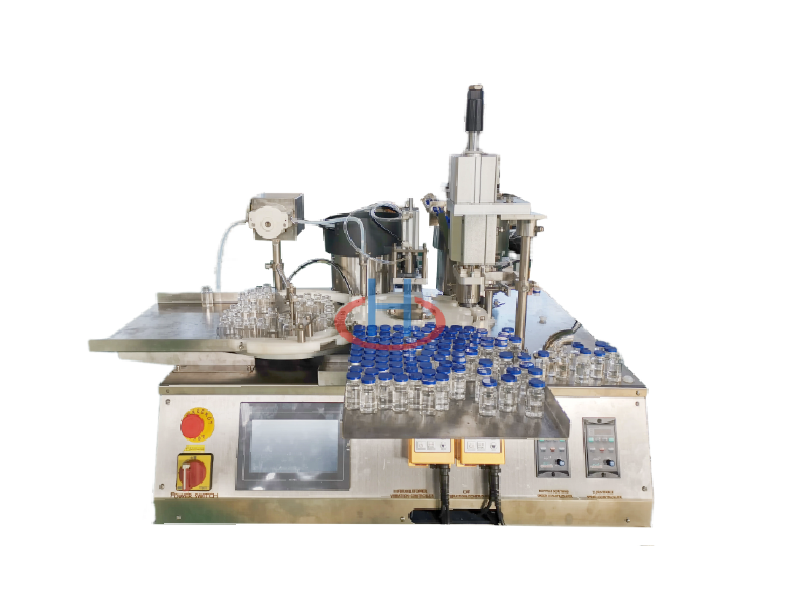

Introducing Our Filling Machines

Our extensive selection of filling machines blends precise engineering with flexible functionality. Designed to accommodate a wide range of products, these machines provide consistent accuracy and dependable performance. Equipped with advanced PLC control systems, customizable filling settings, and intuitive interfaces, they maximize production efficiency. Constructed from premium stainless steel, the machines offer long-lasting durability and straightforward maintenance. Suitable for both small-scale operations and large-volume production, they deliver precise filling solutions while preserving product quality.

Our Filling Machine Range

Why Choose HaoChao's Filling Machines?

Our filling machines are designed to meet the diverse needs of various industries. Whether you're in the food and beverage, pharmaceutical, or chemical sector, we have the perfect solution for you. Here's why businesses choose HaoChao:

High Precision and User-Friendly Operation

Our machines are designed with precision engineering to ensure consistent filling volumes every time, while boosting production efficiency and minimizing downtime. Equipped with variable frequency control, adjustable production speed, automatic counting, and intuitive HMI/PLC systems, they simplify parameter settings and streamline automated production. An automatic shutdown function prevents filling without bottles, enhancing operational safety.

Durability, Reliability, and Versatile Design

Constructed from high-quality stainless steel that meets food safety standards, our machines are durable, easy to maintain, and hygienic. Stable electric power transmission allows simultaneous filling, extruding, and sealing operations. The compact, movable design is ideal for small to medium-sized businesses. With single, double, or four-head configurations, the machines offer versatile filling options, ensuring product safety and a competitive edge.

Filling Machine Parameter Details

At HaoChao, we offer a comprehensive selection of filling machines to cater to different filling needs:

Single Station Eye Drop Bottle Filling Machine

This equipment is a customized eye drop filling machine based on bottle type, suitable for filling, plugging, capping, screwing, and dispensing bottled eye drops. Applicable bottle:5-100ml Production Capacity:30-50 bottles/minute power:2 kw Machine weight:700 kg Machine size:1550*1000*1550mm(length*width*height)

One Station Vial Half-Stoppered Filling Machine

This machine is a half-stoppered filling and capping machine based on customer's vial bottles. Applicable specifications:3-50ml Production capacity:30-50 bottles/min Filling tolerance:≤±1% Wattage(reference):2 kw Dimensions (reference):5000×1300×1550mm

Vial Half-Stoppered Glass Bottle Filling Machine

The vial bottle filling machine is a liquid filling production line customized for customer’s vial bottles. Applicable Specifications:3-50ml Production Capacity:50-80 bottles/min Wattage (Reference);2 kw Dimensions (Reference):5000*1400*1900mm (length*width*height)

Contact Us

Application of HaoChao Filling Machines

Our Service Advantages

Strong Technical Expertise

Backed by a skilled R&D team, the company continuously upgrades and innovates its products, developing high-quality and efficient packaging equipment tailored to various industry needs.

Rigorous Quality Control

Every filling machine undergoes a strict quality testing process to ensure reliability, precision, and long-term performance, meeting international production standards.

Comprehensive After-Sales Support

We provide complete product tracking, free maintenance during the warranty period, and lifelong repair services. Our excellent after-sales support has earned high recognition from users worldwide.

Extensive Industry Application & Global Reach

Our packaging and filling production lines are widely used in pharmaceuticals, food, and daily chemical industries. Products are distributed across China and exported to the Americas, Europe, Asia, and the Middle East.

FAQs

Related Blogs

-

When you want the best filling machines, you should think about five main things. These are product characteristics like viscosity and compatibility, container type and size, automation level, system integration, and reliability with cleanability. These things help you work faster, make better products, and spend your money wisely. The worldwide market for paste filling machines was about USD 3.5 billion in 2023. It is expected to grow fast, which means many industries want these machines. You should always pick a filling machine that fits your production goals and needs.Industry Blogs

When you want the best filling machines, you should think about five main things. These are product characteristics like viscosity and compatibility, container type and size, automation level, system integration, and reliability with cleanability. These things help you work faster, make better products, and spend your money wisely. The worldwide market for paste filling machines was about USD 3.5 billion in 2023. It is expected to grow fast, which means many industries want these machines. You should always pick a filling machine that fits your production goals and needs.Industry Blogs -

Selecting the right equipment for a production line is often a high-stakes decision where visual similarities can be deceiving. While a liquid filler and a paste filler may look nearly identical on the shop floor, the engineering principles governing them differ radically. A machine designed to flow water by gravity will fail catastrophically if tasked with moving cold peanut butter, just as a high-force piston filler may turn a foamy chemical cleaner into a splashing mess.Industry Blogs

Selecting the right equipment for a production line is often a high-stakes decision where visual similarities can be deceiving. While a liquid filler and a paste filler may look nearly identical on the shop floor, the engineering principles governing them differ radically. A machine designed to flow water by gravity will fail catastrophically if tasked with moving cold peanut butter, just as a high-force piston filler may turn a foamy chemical cleaner into a splashing mess.Industry Blogs -

Picking the right liquid filling machine is important. It can help your production line work better. You should match the machine’s features to your product’s thickness, container size, and speed. Some machines have special parts like anti-drip nozzles. They also have adjustable filling speeds and FDA-approved materials. These features help keep things clean and accurate. Think about these points:Industry Blogs

Picking the right liquid filling machine is important. It can help your production line work better. You should match the machine’s features to your product’s thickness, container size, and speed. Some machines have special parts like anti-drip nozzles. They also have adjustable filling speeds and FDA-approved materials. These features help keep things clean and accurate. Think about these points:Industry Blogs

Keep In Touch With Us

Ready to revolutionize your filling process with HaoChao's advanced machines? Contact us today to discuss your requirements and get a solution for your business.

Mob:+86-18221926197

E-mail:rick@sh-haochaojx.com