English

+86-21-57450120

+86-18221926197

+86-18221926197

No.1418 Zhuangliang Road, Zhuanghang Town, Fengxian District, Shanghai 201415, P.R. China

Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

You may ask how much a liquid filling machine costs in 2026. The price changes based on the type you want. Here is a simple chart:

Machine Type | Price Range | Typical Throughput |

|---|---|---|

Manual | $1,000‒$5,000 | 20‒50 bottles/hour |

Semi-Automatic | $5,000‒$20,000 | 50‒200 bottles/hour |

Automatic | $20,000‒$100,000+ | 200‒3,000+ bottles/hour |

There is a big gap in price and cost. This is because each liquid filling machine has special features and different speeds. Experts use market research and company data to set these prices. Brands like Haochao use new technology and are very reliable. When you look at liquid filling machine cost, think about the first price and the cost over time. This helps you find the best deal.

Liquid filling machine prices are very different. The price depends on type, features, and speed. Manual machines cost between $1,000 and $5,000. Semi-automatic machines cost $5,000 to $20,000. Fully automatic machines start at $20,000. Some can cost more than $100,000.

Think about what your business needs. Pick a machine that fits your speed and volume. This helps you not spend too much on things you do not need.

You can save money by buying used or refurbished machines. These machines can be a good deal. Make sure they have a warranty for safety.

Check the total cost to own the machine. This includes energy use and maintenance. Machines that use less energy can save you money over time.

Ask suppliers important questions. Ask about compatibility, speed, and fill accuracy. This helps you choose the best machine for your needs.

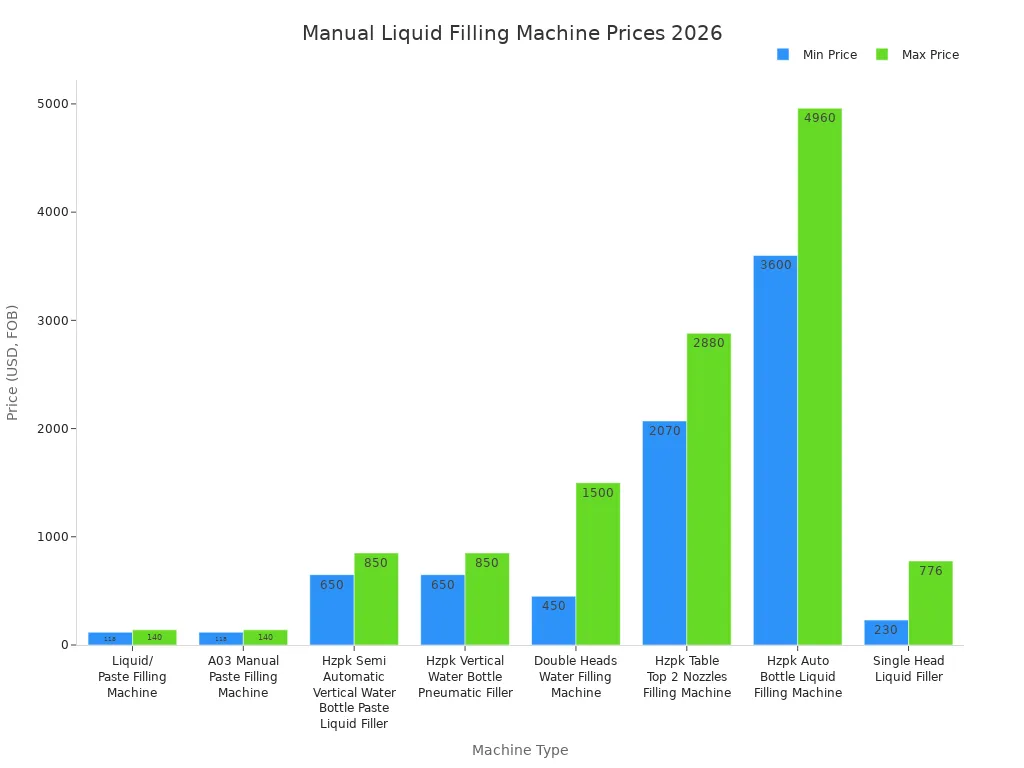

Manual liquid filling machines are easy to use and not expensive. They are good for small jobs or when you need to change things often. In 2026, the cheapest manual machine costs $118. The most expensive one can be $5,000. The price depends on what the machine can do and how it is made. Most simple machines, like the A03 Manual Paste Filling Machine, cost between $118 and $140. If you want a double-head or table-top machine, it can cost up to $2,880. Some manual machines, like the Hzpk Auto Bottle Liquid Filling Machine, can cost as much as $4,960.

Here is a table that shows prices for different manual liquid filling machines:

Machine Type | Price Range (FOB) |

|---|---|

Liquid/Paste Filling Machine | $118 - $140 |

A03 Manual Paste Filling Machine | $118 - $140 |

Double Heads Water Filling Machine | $450 - $1,500 |

Hzpk Table Top 2 Nozzles Filling Machine | $2,070 - $2,880 |

Hzpk Auto Bottle Liquid Filling Machine | $3,600 - $4,960 |

Single Head Liquid Filler | $230 - $776 |

You can see that the price changes with each type and feature. The chart below shows the 2026 price ranges for manual liquid filling machines:

Manual machines are great for small companies or new businesses. They can fill 20 to 50 bottles every hour. This is good for making small amounts. Haochao has manual machines that fill bottles well and are easy to clean.

Semi-automatic liquid filling machines are faster and give you more control. They are good when you need to fill more bottles but do not want to spend too much. In 2026, these machines usually cost between $8,000 and $20,000. Some models cost $8,000 to $11,000, and this includes VAT. Machines for chemicals or special liquids can cost up to $20,000.

Here is a quick table for semi-automatic machine prices:

Product Description | Price Range |

|---|---|

Semi-Automatic Liquid Filling Machine | $8,000 - $11,000 |

Cheap Semi Automatic Chemical Liquid Filling Machine | $10,000 - $20,000 |

Many things can change the price of these machines:

New technology can make the price go up or down.

If more people want these machines, the price can change.

Where you buy the machine can affect the price.

When patents end, machines can get cheaper.

More people buying vitamins and supplements means more machines are needed.

Stricter rules mean machines must be easy to clean and check.

Haochao makes semi-automatic machines with anti-drip nozzles and FDA-approved parts. These features help you follow the rules and keep your work fast.

Fully automatic liquid filling machines are the fastest and can fill the most bottles. They are best for big factories that need to fill hundreds or thousands of bottles every hour. In 2026, these machines start at $20,000. Some can cost over $100,000. The price depends on how much the machine can do, how many filling heads it has, and extra features.

You pay more for better technology, faster speed, and bigger size. For example, the Haochao 8-head Linear Liquid Filling Machine can fill lots of bottles and has features like CIP/SIP cleaning and flow control. These machines help you waste less and work better.

When you buy a fully automatic liquid filling machine, you are making a smart choice for the future. You get faster work, need fewer workers, and your bottles are filled the same way every time. This is good for big companies with lots of orders.

Tip: Always pick a machine that matches how many bottles you need to fill. This way, you do not spend money on a machine that is too big.

The price of a liquid filling machine depends on the type, what it can do, and what you need for your business. Take your time to look at different machines and pick the one that fits you best.

When you want to buy a liquid filling machine, many things change the price. If you know what makes the price go up, you can choose the best machine for your business. Here are the main things that make the cost higher:

Automation tier

Filling technologies

Production capacity

Materials and build quality

Controls and instrumentation

Customization and special features

Brand and after-sales support

Regulatory compliance

Logistics and installation

Let’s look at each thing to see how it changes the price of a liquid filling machine.

How much a machine does by itself is a big reason for price changes. You can pick manual, semi-automatic, or fully automatic machines. Each type costs a different amount and works at a different speed. Manual machines cost the least. Fully automatic machines cost the most because they have more features and fill bottles faster.

Automation Tier | Typical Price Range (USD) |

|---|---|

Manual | $100–$500 |

Semi‑Automatic | $600–$5,000 |

Fully Automatic | $10,000–$100,000+ |

If you want a machine that works alone, you will pay more. These machines help you save time and make fewer mistakes. For example, Haochao has fully automatic machines with anti-drip nozzles and CIP/SIP cleaning. These features help keep your work area clean and fast.

The way a machine fills bottles also changes the price. Some machines use gravity to fill bottles. Others use pumps or flow meters for better control. Machines with advanced technology, like volumetric or flow control systems, cost more money. These systems help you fill bottles more accurately and waste less liquid. If you need to fill thick liquids or want to stop spills, you may need special nozzles or sensors. These cost extra but help you get better results.

Production capacity means how many bottles you can fill in a certain time. If you need to fill lots of bottles every hour, you need a bigger and faster machine. This costs more money. In 2026, machines that fill bottles between 51 and 250 ml are very popular. Many companies want machines that fill lots of bottles quickly. High production costs and the need for cheap packaging also change the price. If you want a machine for big orders, you will pay more, but you get better value.

Machines for 51-250 ml bottles are popular, so they cost more.

Automatic machines are liked because they fill bottles faster.

Companies want machines that are quick and save money.

What a machine is made of and how well it is built can change the price a lot. Machines made with strong, FDA-approved materials last longer and are safer for food, chemicals, or medicine. If you pick a machine with stainless steel parts, you pay more, but you get better safety and fewer problems. Haochao uses good materials to make sure your machine follows the rules and stays clean. Good build quality means you spend less on fixing the machine and get more value over time.

Special changes and extra features can make a liquid filling machine cost more. If you need a machine for special bottles or with unique controls, you pay more. Many companies want machines that can change for different products or packages. This means more machines have adjustable speeds, special nozzles, or smart controls. These features help you work faster and waste less, but they cost extra.

Custom choices and extra features make the price higher because they need special parts.

Advanced automatic systems cost more at first, which can be hard for small businesses.

If you want a machine that can change for many products, you pay more, but you get more options.

Small companies may not have enough money for machines with lots of features.

Tip: Always think about which features you really need. Sometimes, a simple machine works well and saves you money.

When you know what changes the price, you can pick the best machine for your needs. Think about your goals, your budget, and the features that matter most. This helps you get the best deal and a machine that helps your business grow.

Each type of liquid filling machine costs a different amount. Manual machines are the cheapest. You might pay $1,000 to $5,000 for a simple one. Semi-automatic machines cost more, from $8,000 to $20,000. Fully automatic machines are the most expensive. These start at $20,000 and can be over $100,000. Some very advanced machines for drinks can cost more than $2,000,000. The price depends on what the machine can do, how fast it works, and how many bottles it fills each hour.

Here is a table to help you compare:

Machine Type | Average Cost (USD) | Typical Speed (bottles/hour) |

|---|---|---|

Manual | $1,000 – $5,000 | 20 – 50 |

Semi-Automatic | $8,000 – $20,000 | 50 – 200 |

Fully Automatic | $20,000 – $100,000+ | 200 – 3,000+ |

Note: Basic beverage machines usually cost $100,000 to $500,000. Fancy machines with many heads can cost even more.

Liquid filling machines are used in many businesses. In the beverage industry, companies use fast machines to fill lots of bottles every hour. These machines must work quickly to keep up. For example, a big soda factory may buy a system that costs over $500,000 to fill bottles fast and accurately.

In the chemical industry, machines must handle different liquids safely. The price can change if you need special parts or extra safety. A chemical plant might use a semi-automatic machine for small jobs or a fully automatic one for big jobs.

Pharmaceutical companies need machines that follow strict rules. These machines must use FDA-approved materials. They often have anti-drip nozzles and CIP/SIP cleaning. These features make the price higher, but you get better safety and quality.

When you think about the average cost, always look at what your business needs. A higher price at first can help you save money later if the machine fits your goals.

You want to right-size your investment when you buy a liquid filling machine. Start by looking at your real production needs. If you buy a machine that is too big, you will pay more than you need. If you buy one that is too small, you will not meet your goals. Check your current and future capacity. This helps you pick the best machine for your business. Always ask for performance data from suppliers. This lets you see if the machine matches your needs.

You can save money by looking at used or refurbished machines. Many companies sell high-performance liquid filling machine models that have been checked and repaired. Make sure you check the quality and ask about the warranty. Used machines can give you good value if you do not need the newest features. This is a smart way to lower your cost without losing quality.

The price you pay at first is only part of the story. You need to think about the total cost of ownership. This means you look at energy use, repairs, and spare parts. Some machines use energy-efficient motors and smart drives. These features help you save money on utilities. You can also bundle service contracts and spare parts to lower your long-term cost. Always plan for these extra costs before you buy.

You can use cost-saving tips when you talk to suppliers. Try to bundle service and support in your deal. Ask for clear performance data and check what is included in the price. If you buy more than one machine, you may get a better deal. Always compare offers from different suppliers. This helps you get the best value for your money.

Tip: Make a checklist of your needs and compare it with what each supplier offers. This helps you make a smart choice.

Here are some ways to save money when you buy a liquid filling machine:

Choose energy-efficient machines to cut utility costs.

Buy based on real capacity needs.

Bundle service and spare parts.

Consider refurbished machines with a warranty.

Ask for performance data from suppliers.

You need to know your production needs before you buy a liquid filling machine. Start by looking at your product and packaging. Here is a step-by-step way to do this:

Define your product. Think about thickness, bubbles, temperature, and how much you want to fill.

Check your packaging. Look at the type, shape, and size of your bottles or containers.

Set your production targets. Decide how many bottles you want to fill each hour or day.

Shortlist filling methods. Pick the best way to fill based on your product and packaging.

Choose your automation level. Decide if you want manual, semi-automatic, or fully automatic.

List important features. Think about cleaning, safety, and special certifications.

Research vendors. Find companies that know your industry and ask for quotes.

Test the machine. Try your product on the machine to see how it works.

Check the total cost. Look at the price, repairs, and running costs.

Make your choice. Use your data and tests to pick the best option.

Tip: Write down your needs and goals. This helps you compare machines and make a smart choice.

You want to get the most value for your money. Use this table to help balance your budget with what you need:

Consideration | Description |

|---|---|

Type of Liquid | Check if your product needs a special filling method. |

Budget | Know how much you can spend. Prices change a lot between machines. |

Space Constraints | Measure your space. Some machines need more room than others. |

Level of Automation | Decide if you need semi-automatic or fully automatic for your work. |

Maintenance Needs | Ask how easy it is to fix and get spare parts. |

Scalability | Think about future growth and if the machine can handle more bottles later. |

Note: Always plan for the future. A machine that grows with your business saves money over time.

Before you buy, ask suppliers these important questions:

Does my production volume fit a fully automated option?

How much can I save by reducing product waste?

Will the bottles line up well with the fill nozzles?

What type of container will I use, and does the machine handle it well?

What is my target production speed, and which machine matches it?

Can this machine connect with other equipment in my line?

Will my current volume justify the investment?

What fill accuracy can I expect, and how will it affect my costs?

How does the machine handle my product to prevent problems?

Asking these questions helps you avoid surprises and choose the right liquid filling machine for your needs.

In 2026, the price of a liquid filling machine changes with its type, speed, and features. Picking the right machine for your business helps you make more products and waste less. This means you can earn more money.

Metric | Before | After Right Choice |

|---|---|---|

Labor | 4 operators | 1 operator |

Product Giveaway | ~4% | <0.5% |

Daily Output | 2,000 | 10,000 |

Payback Period | — | 7 months |

Here are some steps to help you:

Think about your budget, how fast you need to work, and how much you want to make.

Look at what people say about the brand and read reviews from other customers.

Use this guide to check how accurate the machine is, if it follows the rules, and what technology it uses.

This guide can help you pick the best machine for your needs.

You should look at your product type, bottle size, and how many bottles you need to fill each day. Match your needs with the machine’s speed and features.

Most machines last 8–15 years with regular care. You can extend the life by cleaning and servicing the machine as the supplier recommends.

Yes, many machines handle different liquids. You may need to change settings or parts for each product. Always check with your supplier for compatibility.

You should clean the machine after each use. Check for worn parts and replace them as needed. Follow the supplier’s maintenance schedule for best results.