English

+86-21-57450120

+86-18221926197

+86-18221926197

No.1418 Zhuangliang Road, Zhuanghang Town, Fengxian District, Shanghai 201415, P.R. China

| Availability: | |

|---|---|

| Quantity: | |

The vial bottle filling machine is a liquid filling production line customized for customer’s vial bottles. The equipment consists of vial bottle filling, half-stoppering, a capping machine, and a self-adhesive labeling machine. Adopting rotary table bottle feeding, peristaltic pump filling, positioning type stopper plugging, filling machine equipped with hundred level laminar flow, vibration tray cap sorting, positioning capping, cap rolling, and labeling. The entire line equipment runs stably, with human-machine interface settings, simple operation, and is widely used in food, pharmaceutical, chemical industries and scientific research fields.

This equipment has single station and dual station models.

Characteristics

1. All electrical components are from well-known brands.

2. Adopting three-level management permissions.

3. The bottle positioning device ensures accurate alignment between the bottle mouth and the discharge port.

4. No filling without bottles, no capping without bottles, automatic shutdown without bottles or caps.

5. The system has two working modes: manual mode and automatic mode.

6. The control system records and displays alarm information, current shift output and total output.

7. Human machine interface equipment, intuitive and convenient operation, PLC control.

8. Variable frequency control, adjustable production speed, automatic counting.

9. Vibration tray sorting stopper and cap, positioning type plugging and capping.

Technical Parameter

Applicable Specifications | 3-50ml |

Production Capacity | 50-80 bottles/min |

| Power | Customized |

Wattage (Reference) | 2 kw |

Dimensions (Reference) | 5000*1400*1900mm (length*width*height) (Height includes the 100-level dust protective cover and Laminar flow hood) |

Detail Display

Vial bottle filling equipment

Filling and stoppering

Simple operation and intelligent control

Full color touch screen and PLC control system

Rotary bottle feeding machine,

Cap installing and rolling machine

Round bottle labeling machine

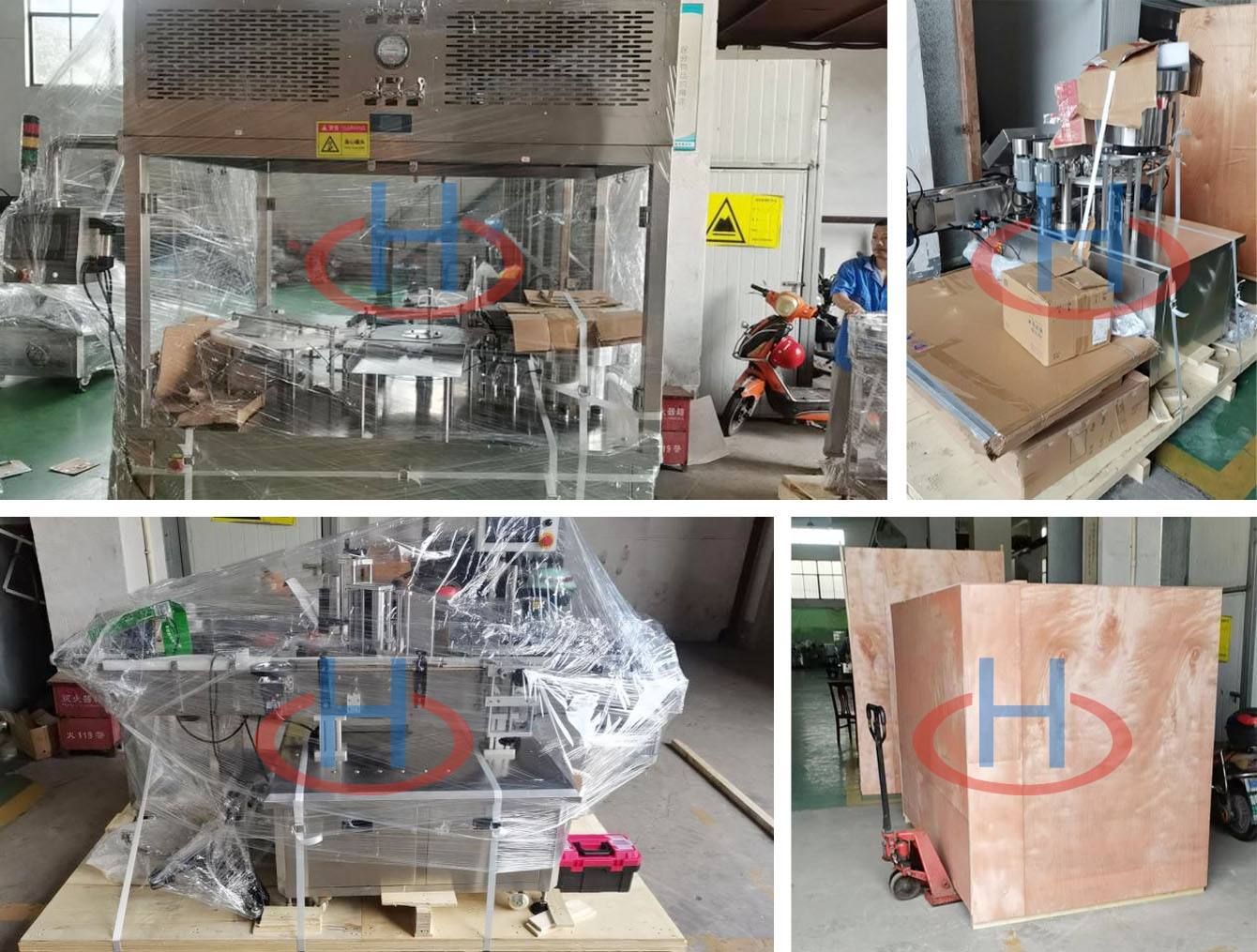

Packing And Delivery

Production Capacity: Efficiently fills 2400 to 3000 vials per hour, optimizing your production line.

Versatile Vial Compatibility: Suitable for vials ranging from 1 to 20ml.

Accurate Measurement: Achieves measurement accuracy within ± 1-5%, ensuring precision in every fill.

Advanced Stoppering: Pneumatic stopper feeding with full/half stopper options, preventing stoppering without vials.

Capping Method: Utilizes a three-knife centrifugal system for higher efficiency.

Peristaltic Pump: Easy to adjust, clean, and change, enhancing operational flexibility.

Plunger Pump: Dedicated for a single filling volume, ensuring consistency.

PTFE Turntable: Minimizes bottle wear, prolonging equipment lifespan.

Safety and Sterility: Glass cover protection and laminar flow hood to maintain a sterile environment.

Cosmetics: Perfect for perfume and liquid products, offering customizable filling volumes.

Food & Beverage: Efficiently handles water, juice, milk, and beer filling with adjustable settings.

Chemicals: Suitable for viscous liquids and oils, enhancing your production line's flexibility.

Liquids: Water, juice, milk, essential oils, perfumes

Viscous Substances: Oils, chemical solutions

Versatility: Compatible with peristaltic, magnetic gear, and vacuum pump systems.

Customization: Tailor filling volumes to match your product specifications.

Efficiency: Streamline production with automated, high-precision filling.

More Information About Haochao